Complēt™ Long Fiber Reinforced Structural Thermoplastics

Metal Replacement Solution

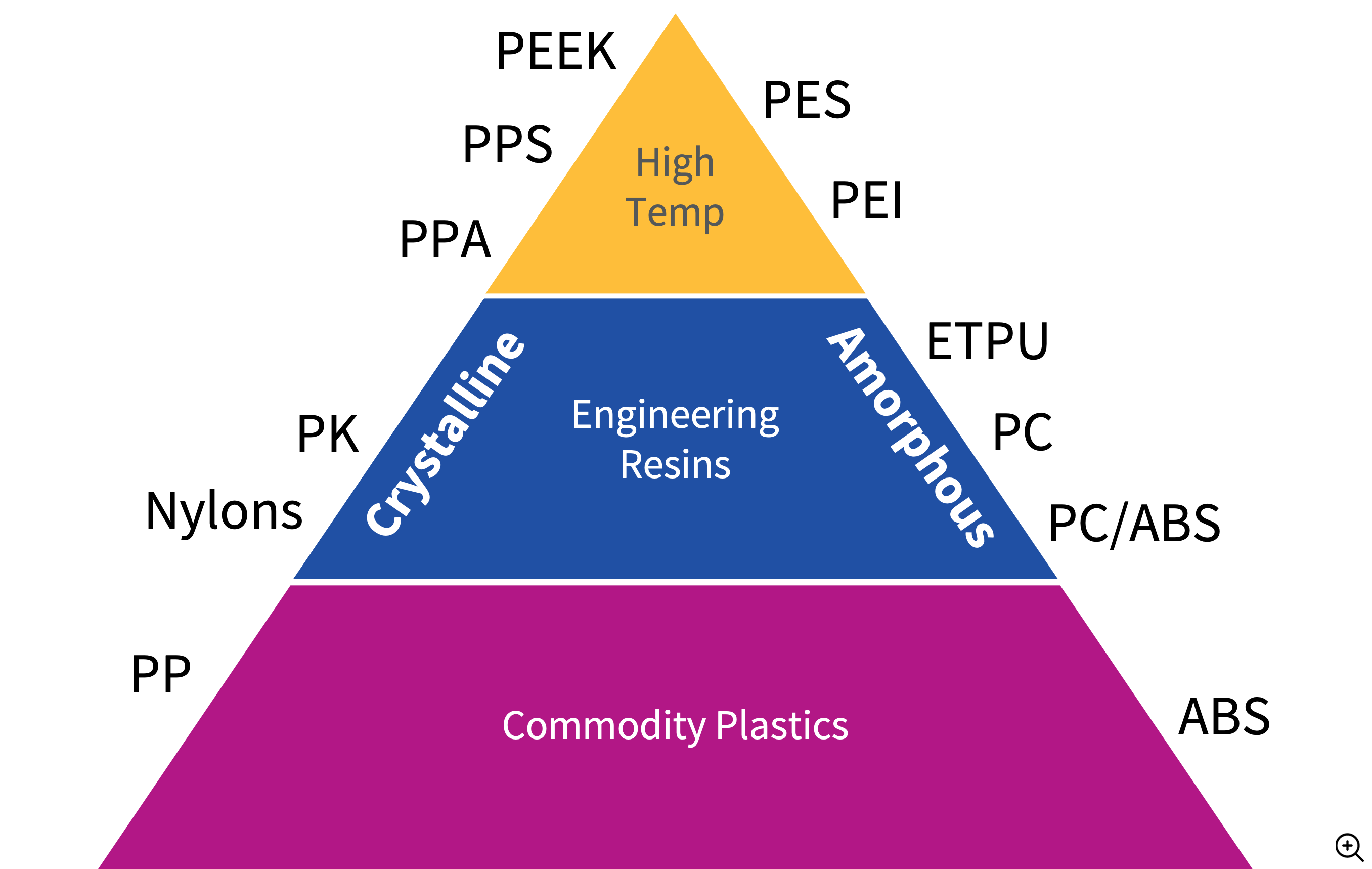

Complēt™ long fiber reinforced thermoplastics are structural injection molding composites with metal replacement performance. This product line encompasses a large net of specialty solutions that are tailored to solve light weighting initiatives for a variety of industries. Fiber reinforcements include long glass fiber, long carbon fiber and long hybrid (glass + carbon) fiber. Resin technologies utilized in these formulations include a breadth of options including a variety of polyamides, rigid thermoplastic polyurethanes and specialty resin solutions (such as PES, PEI, PEEK).

These products showcase or continually advancing technologies and formulation capabilities, continually expanding new solutions into new markets eager for metal replacement alternatives. This includes our additional product offerings of Complēt PKE Polyketone Formulations, Complēt Moisture Resistant Nylons and Complēt REC Recycled Content grades.

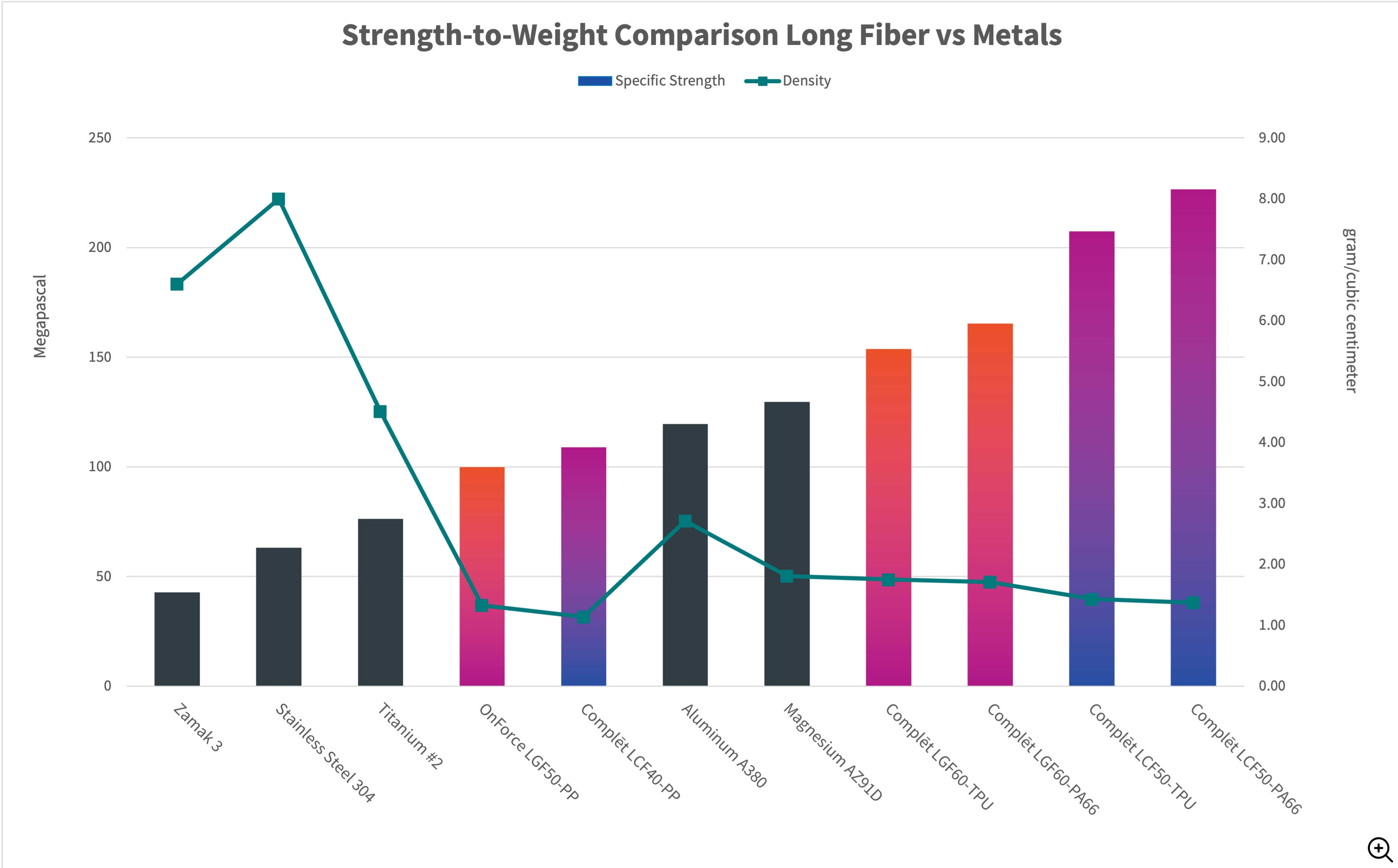

With appropriate material selection and part design optimization, long carbon fiber materials can reduce the weight of components up to 40% compared to aluminum. Additional benefits include high strength and stiffness performance, creep resistance, fatigue endurance, elevated and low temperature performance, dimensional stability, and corrosion and chemical resistance.

Customized, single-pellet solutions are highly encouraged – utilize our formulation expertise to make your production process as efficient as possible. Color matching, UV performance enhancements and lubrication additives are just a few of the many performance additive solutions that we offer.

Benefits

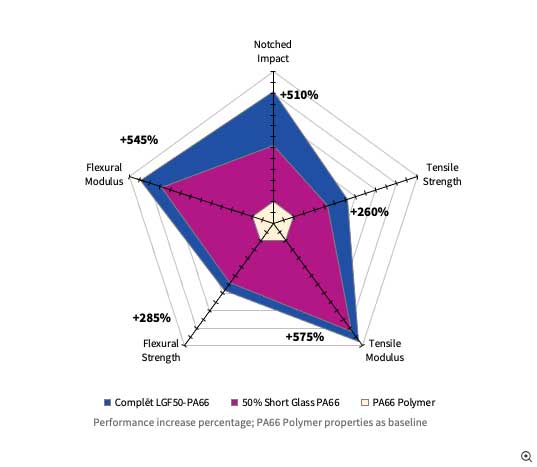

- Improved strength and toughness vs. short fiber

- High strength-to-weight ratio

- Retains performance across low and elevated temperatures

- Load carrying creep and fatigue resistance

- Excellent dimensional stability

- Very good corrosion and chemical resistance

- Can be processed on standard injection molding machines

Properties and Comparisons

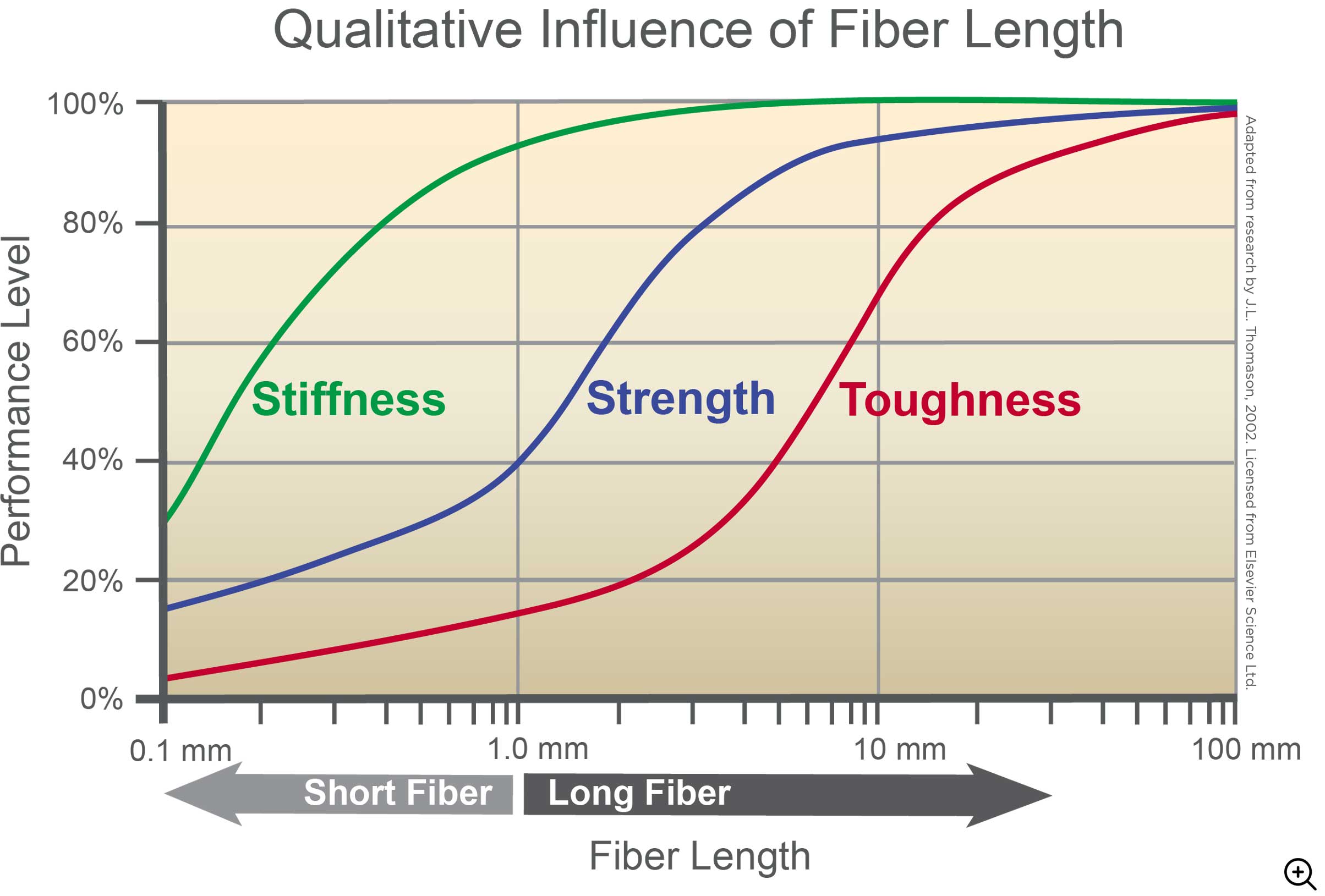

Complēt long fiber pellets are cut to a 12mm chop length, with unidirectional fiber reinforcement throughout the pellet (12mm pellet = 12mm fiber length). See how the fiber length directly correlates to increased stiffness, strength and impact performance. Pellet lengths can be tailored between 6mm and 15mm, but the typical length is 12.

| Long Fiber Technologies | Applications | Description/Product Features |

|---|---|---|

| Complēt™ LGF | Transportation underhood and powertrain, off-road recreational vehicles, automotive aftermarket parts, portable tools and equipment, and healthcare | Long glass fiber reinforced engineering resins with enhanced mechanical properties that obtain metal-like structural capabilities. Provides high impact and fatigue resistance |

| Complēt™ LCF | Sports and recreation gear, aerospace interiors, robotics, and industrial equipment | Higher performance long carbon fiber reinforced thermoplastics for weight sensitive applications or more load-carrying capability |

| Complēt™ Hybrid | Sports and recreation gear or automotive underhood and powertrain | Synergistically combines long carbon and long glass fiber together in a unified material to optimize performance and cost |

| Complēt™ MT | Sports and recreation gear or industrial equipment | Maximum toughness, long fiber reinforced nylon 6 or 66 formulated for extra impact and fatigue resistance for demanding applications |

| Complēt™ Moisture Resistant | Automotive, powersports, automotive aftermarket parts and consumer applications | Long fiber reinforced nylon 6 or 66 composites providing consistent performance in moisture-rich environments. Long glass fiber formulations offer surface appearance free of visible fiber |

| Complēt™ REC | Sports & recreation gear, office furnishings, or automotive | Post-consumer recycled (PCR) and post-industrial recycled (PIR) resins up-engineered with long fiber reinforcement. Recycled resin content customizable to meet performance and sustainability requirements |

| Complēt™ PKE | Pipes, tubing, fluid management, electrical connectors, battery components, under-the-hood fuel/chemical contact components, non-structural interior components, oil and gas components | Long glass fiber reinforced polyketone that delivers excellent chemical resistance, low moisture uptake, and dimensional stability similar to nylon (PA6 and PA66). They also offer over 2x higher impact properties than short fiber reinforced solutions, while maintaining impact properties in cold and demanding environments |

| NAME | CATEGORY | DESCRIPTION | |

|---|---|---|---|

| Automotive Aftermarket Side Step | Case Study (Snapshot) | Moisture-resistant Complēt™ long glass fiber reinforced formulation improves strength, design freedom, and finish | View |

| Internal Frame Structure for Hunting Backpack | Case Study (Snapshot) | Injection molded Complēt™ long carbon fiber reinforced nylon composite delivered high stiffness and low weight while simplifying manufacturing | View |

| Advanced Simulation Capabilities for Structural Applications | Video | Learn more about enhanced modeling and design technology capabilities to more accurately predict long fiber reinforced thermoplastic performance in structural metal replacement applications | View |

| Aerospace Passenger Seating Components | Case Study (Snapshot) | Complēt™ long carbon fiber reinforced PES composite reduced weight 40% and met FAA requirements for flammability and survivability | View |

| Aerospace Seating Component | Case Study (Snapshot) | Complēt™ LCF PES formulation delivered lightweighting for an aerospace seat component through metal replacement (replacing aluminum) | View |

| Automotive Aftermarket Motor Mount | Case Study (Snapshot) | Complēt™ 50% long glass fiber reinforced specialty PA66 thermoplastic replaces die-cast aluminum | View |

| Automotive Aftermarket Overview | Application Overview | Overview of the needs within automotive aftermarket and the long fiber thermoplastic (LFT) technologies to meet those needs | View |

| Automotive Removable Roof Bracket | Case Study (Snapshot) | Complēt™ long carbon fiber reinforced polyphthalamide composite replaced steel in bracket securing roof panels and achieved an 80% weight reduction | View |

| Automotive Steering Column Bracket | Case Study (Snapshot) | Complēt™ long carbon fiber reinforced nylon composite replaced metal steering column supports and lowered weight by 50% | View |

| Avient Long Fiber Technology | Video | Provides structural performance that can go head-to-head with metals at a fraction of the weight | View |

| Axial Fan Blade | Case Study (Snapshot) | Explore how Complēt™ LFT replaced aluminum, resulting in thinner, lighter, stronger industrial fan blade | View |

| Benefits of LFT | White Paper | Explore the unique capabilities of specialty long fiber reinforced composites | View |

| Bettcher Industries – Case Study | Case Study | Metal replacement, design improvements and Complēt™ long fiber technology provide powerful solution for Bettcher Industries | View |

| Complēt™ & OnForce™ Long Fiber Reinforced Thermoplastic Composites - Processing Guide | Processing & Design Guides | Guidance on key elements of preparation and molding process for Complet & OnForce LFT | View |

| Complēt™ and OnForce™ Long Fiber Reinforced Thermoplastic Composites - Design Guide | Processing & Design Guides | Download this guide to learn how to design ribs, bosses, and other features that stand the test of time, better ways to process LFT materials, what to do to minimize part defects and more about Complēt™ and OnForce™ Long Fiber Reinforced Thermoplastic Composites | View |

| Complēt™ LFT - Stronger. Tougher. Lighter. | Video | Compare the strength, toughness and weight of long fiber thermoplastics against other materials | View |

| Complēt™ LFT Automotive Aftermarket Side Step | Case Study | Complēt™ Long Fiber Reinforced Structural Thermoplastics used in automotive aftermarket side step | View |

| Complēt™ Moisture Resistant Long Fiber Thermoplastic Nylons | Video | Complēt™ Moisture Resistant Long Fiber Thermoplastic Nylons provide gradual moisture uptake to maintain structural properties longer | View |

| Complēt™ Moisture Resistant Nylons | Product/Service Overview | Environmentally stabilized nylon 6 and 6/6 long fiber composites for application intermittently exposed to water high humidity that require consistent structural performance | View |

| Complēt™ REC Long Fiber Reinforced Thermoplastics | Product/Service Overview | Performance data and information on Complēt REC long fiber reinforced composites incorporating recycled resin | View |

| Complēt™ REC Long Fiber Reinforced Thermoplastics | Video | Introducing Complēt REC long fiber reinforced thermoplastics (LFT) containing post consumer and post industrial recycled material | View |

| Complēt™ REC Long Fiber Reinforced Thermoplastics (Chinese) | Video | Introducing Complēt REC long fiber reinforced thermoplastics (LFT) containing post consumer and post industrial recycled material (Chinese language version) | View |

| Complēt™/OnForce™ LFT Overview | Product/Service Overview | Optimize stiffness, strength, and toughness to obtain structural performance with lightweight long fiber reinforced thermoplastics. | View |

| Craftech Non-Metallic Fasteners | Case Study (Snapshot) | Custom formulated and pre-colored Complēt™ long glass fiber reinforced ETPU composite offered corrosion resistance while matching the structural capabilities of metal fasteners | View |

| Engineered Materials for EV Batteries | Infographic | Discover engineered polymers to advance battery design and performance | View |

| Engineered Polymer Materials for EV Batteries | Video | Learn more about advanced polymer technologies that enhance EV battery design and performance to enable benefits such as extended vehicle range, lightweighting and sustainability. | View |

| Environmentally Stabilized Composites | White Paper | Learn more about moisture resistant nylon long fiber reinforced composites | View |

| Injection Molded Composite Baseball Bat | Case Study (Snapshot) | Complēt™ long carbon fiber reinforced composites allows deployment of injection molded material solution for design flexibility and customization | View |

| Innovative Office Furniture Task Chair | Case Study (Snapshot) | Strategically positioned unidirectional tape inserts overmolded with Complēt™ long glass fiber reinforced nylon composite provide fatigue endurance to allow part reduction for office chair | View |

| LFT Basics - Understanding Long Fiber Thermoplastics | Webinar | Learn about long fiber technology and why it’s replacing metal. | View |

| Long Fiber Reinforced Thermoplastic (LFT) Solutions for Bicycles | Application Graphic | Explore long fiber reinforced thermoplastic (LFT) solutions that meet various bicycle application demands | View |

| Long Fiber Technologies Application Development | Product/Service Overview | Avient long fiber technologies application development center bulletin highlighting services including design support, material validation, simulation support, and in-house prototyping | View |

| Long Fiber Thermoplastics for Brackets and Latches | Application Overview | Key benefits and data for long fiber thermoplastic (LFT) to replace metal for brackets and latches | View |

| Optimizing Automotive Structural Component Designs with Advanced Modeling | Article | Learn how virtual capabilities can improve performance. | View |

| Personal Watercraft OEM Steering Column | Case Study (Snapshot) | Complēt Hybrid Moisture Resistant Composite provided part consolidation, design consultation, and robust FEA support | View |

| Piranha Marine Propeller | Case Study (Snapshot) | Complēt™ MT Long Glass Fiber Reinforced Nylon 6 improved durability and vibration damping allowing the blades to flex and absorb energy from minor impacts | View |

| Piranha Propeller - Case Study | Case Study | Read how long fiber composites helped Piranha Propellers add toughness and design flexibility | View |

| Replacing Aluminum with Long Fiber Thermoplastics (LFT) | Application Overview | Key factors and comparisons to consider when replacing aluminum with long-fiber-reinforced thermoplastic (LFT); including processing and material performance summaries | View |

| Rethinking Materials for Automotive Aftermarket Parts | Article | Read more about how automotive aftermarket parts are making the switch from metal to plastic by using long fiber thermoplastics | View |

| Scorpyd Crossbow Integrated Rail and Riser | Case Study (Snapshot) | Complēt™ long carbon fiber reinforced ETPU composite along with product design and performance analysis services create industry-first integrated rail and riser assembly for Scorpyd Crossbow | View |

| Seat Pan for Off-Road Recreational Vehicle | Case Study (Snapshot) | Complēt™ long glass fiber reinforced nylon composite consolidated multiple metal parts to streamline manufacturing and assembly of an ATV seat pan | View |

| Services Capabilities Overview | Product/Service Overview | Discover the comprehensive technical services available through Specialty Engineered Materials at Avient to assist customers | View |

| Snowmobile Application Material Solutions | Application Graphic | Explore a range of material solutions for snowmobiles and accessories | View |

| Snowmobile Engine Mounting Bracket | Case Study (Snapshot) | Complēt™ long carbon fiber reinforced nylon composite replaced aluminum to provide better fatigue resistance and reduce weight | View |

| Step Linkage Automotive Aftermarket Part | Case Study (Snapshot) | Complēt™ LGF, moisture-resistant grade delivers improved performance and cost savings for aftermarket parts manufacturer | View |

| Support Yoke for Hanging Industrial Motor | Case Study (Snapshot) | Complēt™ long glass fiber reinforced nylon composite supports the weight of a 25-pound motor without creep while being lower in weight and less costly to produce | View |

| Trail Bicycle Rear Suspension Linkage | Case Study (Snapshot) | Complēt™ long carbon fiber reinforced ETPU composite reduced weight 33% and performance analysis services confirmed metal-to-thermoplastic conversion success | View |

| Unified Seat Shell for Off-Road Recreational Vehicle | Case Study (Snapshot) | Complēt™ long glass fiber reinforced nylon composite consolidated multiple metal components into a unified seat shell permitting weight and cost reductions | View |

| Wheelchair Caster Wheels | Case Study | Customer success with Complēt™ Long Fiber to introduce lightweight composite caster wheels for improved wheelchair mobility | View |

| Wheelchair caster wheels | Case Study (Snapshot) | Complēt™ long carbon fiber (LCF) composites replaced aluminum to reduce weight and enable design freedom for a wheelchair OEM | View |